These devices allow for non-destructive testing (NDT), enabling the detection of corrosion, wear, and material thinning before they become critical issues.

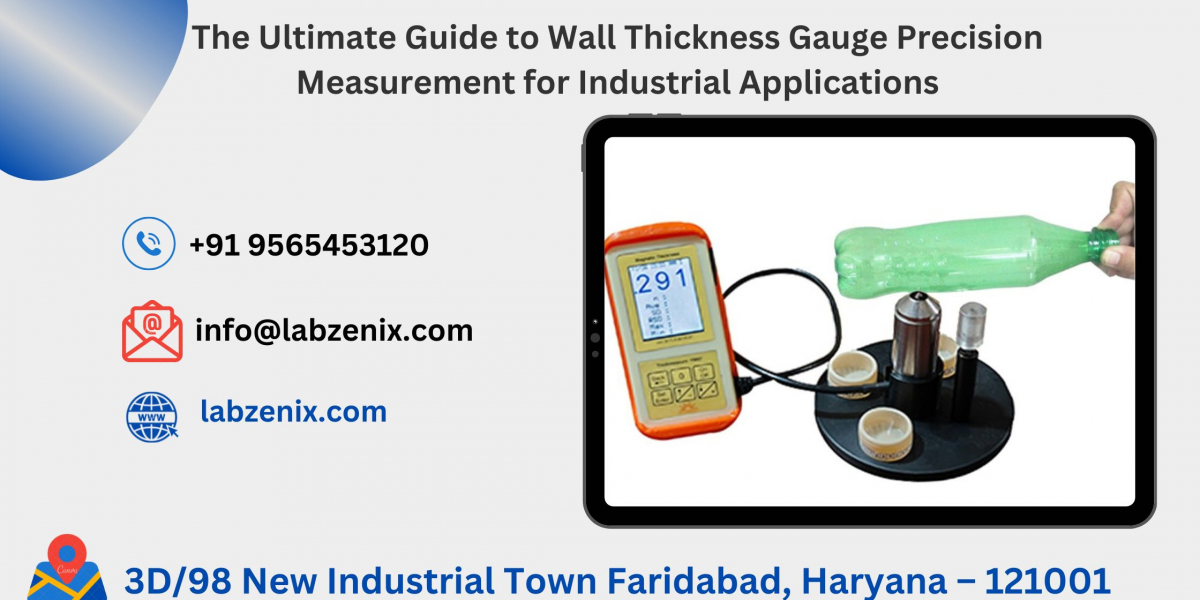

At Labzenix.com, we offer top-quality wall thickness gauge that provide accurate, reliable measurements to meet the highest industry standards. In this article, we’ll explore what wall thickness gauges are, the types available, and their importance across various sectors.

What is a Wall Thickness Gauge?

A Wall Thickness Gauge is a non-destructive tool used to measure the thickness of materials like metals, plastics, glass, and coatings. It helps detect issues like corrosion, wear, and material degradation without causing any damage. By providing accurate measurements, these gauges play a vital role in quality control, safety inspections, and preventive maintenance.

Types of Wall Thickness Gauges

Different types of wall thickness gauges are suited for specific applications and materials. Let’s look at the most common ones:

1. Ultrasonic Thickness Gauges

- How it works: Uses ultrasonic sound waves to measure thickness.

- Ideal for: Metals, plastics, ceramics, and composites.

- Key benefits: High precision in detecting internal defects, corrosion, and material thinning. Ideal for testing hard-to-reach areas.

2. Magnetic Induction Thickness Gauges

- How it works: Measures coating thickness on ferrous (magnetic) materials using the material's magnetic properties.

- Ideal for: Measuring the thickness of coatings on metals such as steel.

- Key benefits: Provides fast, reliable measurements, commonly used in automotive, construction, and industrial coatings.

3. Eddy Current Thickness Gauges

- How it works: Measures thickness using eddy currents induced in non-ferrous materials.

- Ideal for: Non-ferrous metals like aluminum and copper, and protective coatings.

- Key benefits: Ideal for measuring thin coatings like paint or anodized layers, typically used in aerospace and electronics.

Why Use a Wall Thickness Gauge?

Wall thickness gauges offer numerous advantages, making them essential tools for professionals:

✅ Non-Destructive Testing (NDT): No damage to the material, ensuring it remains intact for future use.

✅ Precision & Accuracy: High-accuracy measurements that ensure compliance with safety standards.

✅ Quick & Efficient: Instant, reliable results that save time and reduce inspection delays.

✅ Versatile: Works on a wide range of materials including metals, plastics, and coatings.

✅ Preventative Maintenance: Early detection of corrosion and material thinning, preventing costly failures.

Industries That Rely on Wall Thickness Gauges

Wall thickness gauges are widely used in industries where material integrity is vital:

? Manufacturing: Verifies material thickness to ensure products meet safety and regulatory standards.

? Aerospace: Monitors aircraft parts for thinning materials that could impact performance.

? Oil & Gas: Detects corrosion in pipelines and equipment to prevent leaks and failures.

? Shipbuilding & Marine: Ensures the safety and durability of ship hulls by detecting corrosion or thinning.

? Construction: Ensures that materials in buildings and infrastructure meet required thickness for strength and durability.

How to Choose the Right Wall Thickness Gauge

When selecting a wall thickness gauge, consider the following factors:

✔ Material Type: Make sure the gauge is suitable for the material you're measuring (metal, plastic, coating, etc.).

✔ Measurement Range: Select a gauge that covers the required thickness range for your application.

✔ Accuracy: Choose a gauge that offers high accuracy for critical measurements.

✔ Portability: A lightweight, digital gauge with easy-to-read displays is ideal for field use.

Why Buy from Labzenix.com?

At Labzenix.com, we provide high-quality wall thickness gauge testing designed for reliability and precision. Whether you're in manufacturing, oil & gas, construction, or any other industry, our gauges ensure accurate results for your inspection and quality control needs.

? Looking for top-rated wall thickness gauges? Visit Labzenix.com today to find the perfect tool for your application!